Beste Casino Zonder CRUKS in Nederland (2026)

Het aantal Nederlandse spelers dat op zoek is naar een casino zonder CRUKS neemt snel toe. Deze goksites opereren buiten het toezicht van de Nederlandse kansspelautoriteit en bieden onbeperkte toegang, snelle registratie en minder beperkingen. Hieronder hebben we de beste casino's zonder CRUKS op een rijtje gezet, die allemaal Nederlandse spelers accepteren en een veilige spelervaring van hoge kwaliteit met geweldige bonussen bieden.

Toplijst online casino's zonder CRUKS van 2026

- 0xbet – Duik in de eersteklas game-ervaring van het beste casino zonder CRUKS!

- Wizebets – Slim spelen, probleemloos opnemen, geen CRUKS nodig.

- Jacktop – Grote jackpots, geen beperkingen, totale vrijheid.

- Nolimitbet – Verleg je grenzen met een casino dat je nooit tegenhoudt.

- Playboom24 – Non-stop actie en explosieve bonussen 24/7.

- Casino-sky – Bereik nieuwe hoogten in gokken zonder CRUKS.

- Samiland – Ontdek een wereld van gokkasten voorbij de Nederlandse grenzen.

- Heycasino – Vriendelijk ontwerp, snel spelen, geen CRUKS gedoe.

- Voltslot – Vol energie en open voor Nederlandse spelers.

- Betizy – Speel op jouw manier zonder onderbrekingen.

- Lucky-trunk – Boordevol geluk, gratis van CRUKS.

- Taikaspins – Magische spins wachten in dit casino zonder CRUKS.

- Scibet – Zet slim in met veilige, onbeperkte gameplay.

Online casino's zonder CRUKS - Uitleg

Benieuwd wat het betekent als een online casino geen CRUKS heeft? Hieronder leggen we uit wat deze casino's zijn, wat de legale situatie in Nederland is en waarom ze steeds populairder zijn geworden onder Nederlandse spelers.

Wat is een casino zonder CRUKS?

Een casino zonder CRUKS is een goksite die niet is aangesloten bij het Nederlandse zelfuitsluitingsregister. Deze casino's opereren onder buitenlandse licenties, zoals die van Curaçao of Malta. Dit betekent dat Nederlandse spelers zich kunnen registreren en kunnen spelen zonder beperkt te worden door nationale regelgeving.

Deze casino sites bieden meestal hogere bonussen, minder beperkingen en toegang tot internationale spellen. Ze zijn populair vanwege hun gebruiksgemak en anonimiteit. Hoewel ze niet onder toezicht staan van de Nederlandse autoriteiten, handhaven gerenommeerde opties nog steeds de normen voor licenties en fair play.

Is het legaal om te spelen bij een casino zonder CRUKS?

De Nederlandse wet verbiedt het aanbieden van kansspelen zonder vergunning, maar spelers zelf worden niet gestraft als ze zich aansluiten bij buitenlandse casino's. Dit zorgt voor een juridisch grijs gebied. Dit creëert een juridisch grijs gebied. Hoewel deze websites zich niet actief op Nederlandse gebruikers mogen richten, is toegang vanuit Nederland nog steeds mogelijk.

Veel casino's gebruiken geovriendelijke betalingsopties en ondersteunen de Nederlandse taal, ook al is het onofficieel. Het is belangrijk voor spelers om ervoor te zorgen dat het casino een geldige internationale licentie heeft en betrouwbare klantenservice biedt.

Waarom Nederlandse gokkers spelen in casino's zonder CRUKS?

Veel Nederlandse spelers kiezen voor een casino zonder CRUKS vanwege de vrijheid die ze bieden. Deze casino sites bieden eenvoudigere registratieprocessen, flexibelere stortingslimieten en ononderbroken toegang tot games. In tegenstelling tot Nederlandse gereguleerde casino's zijn er geen verplichte pauzes, ID-controles of nationale blokkades.

Spelers die zich vrijwillig hebben geregistreerd bij CRUKS en nu opnieuw willen spelen, vinden deze casino's vaak een toegankelijkere optie. De ruimere keuze aan bonussen en promoties draagt ook bij aan hun groeiende aantrekkingskracht.

Overzicht van de beste casino's zonder CRUKS

Op zoek naar de beste casino's zonder CRUKS? Ons team heeft tientallen goksites getest om je de top vijf aan te bieden op basis van veiligheid, snelheid, bonussen en gebruikerservaring. Laten we in de top duiken.

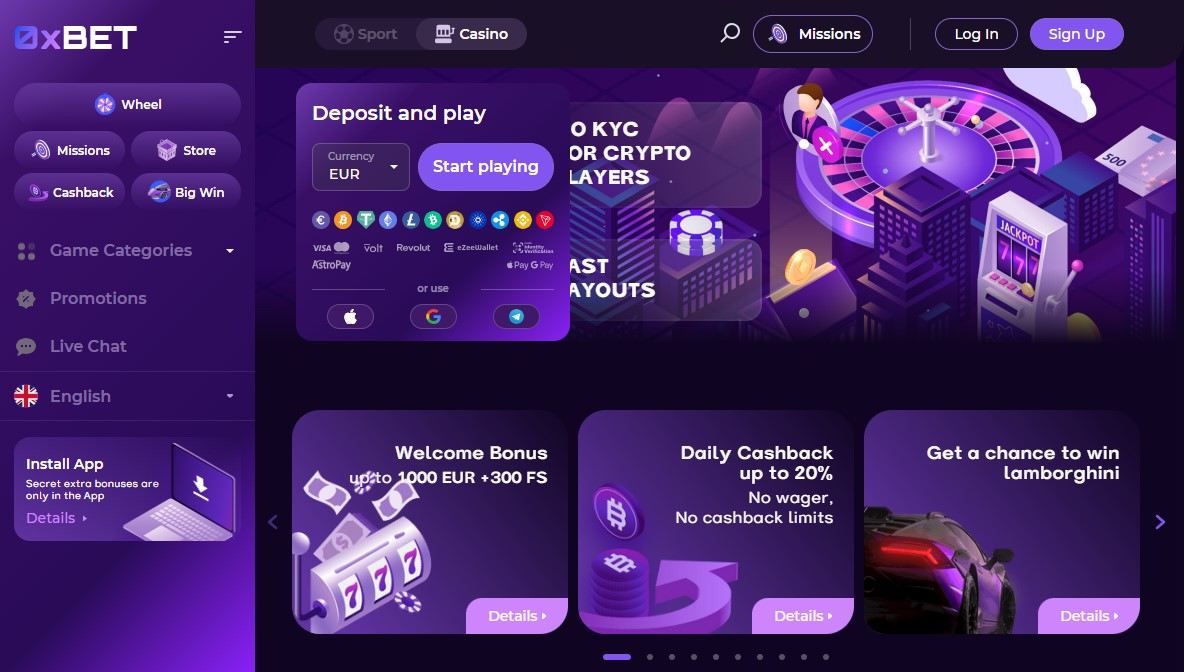

1. 0x.bet – Top online casino zonder CRUKS

0x.bet neemt de toppositie in voor zijn allround uitmuntendheid. Met een strak design, snelladende games en royale bonussen is het een favoriet voor Nederlandse spelers die op zoek zijn naar een hoogwaardige ervaring zonder CRUKS-beperkingen.

Het biedt duizenden games van toonaangevende aanbieders en een soepel registratieproces. Of je nu van gokkasten, live casino of cryptogokken houdt, 0x.bet levert met stijl.

Met sterke beveiligingsprotocollen en een Curaçaose licentie biedt 0x.bet zowel vrijheid als gemoedsrust, waardoor het de beste keuze is voor 2026.

- Voordelen

- Enorme verscheidenheid aan spellen van topaanbieders

- Ondersteunt zowel fiat- als cryptobetalingen

- Soepele gebruikersinterface en mobielvriendelijk

- Nadelen

- KYC vereist voor eerste opname

| Bonus | 700% tot €600 + gratis spins |

|---|---|

| Snelheid van uitbetaling | 24–72 uren |

| KYC | Ja |

| Betaalmethoden | VISA, MasterCard, Paysafecard, Neteller, Skrill, crypto, bankoverschrijving |

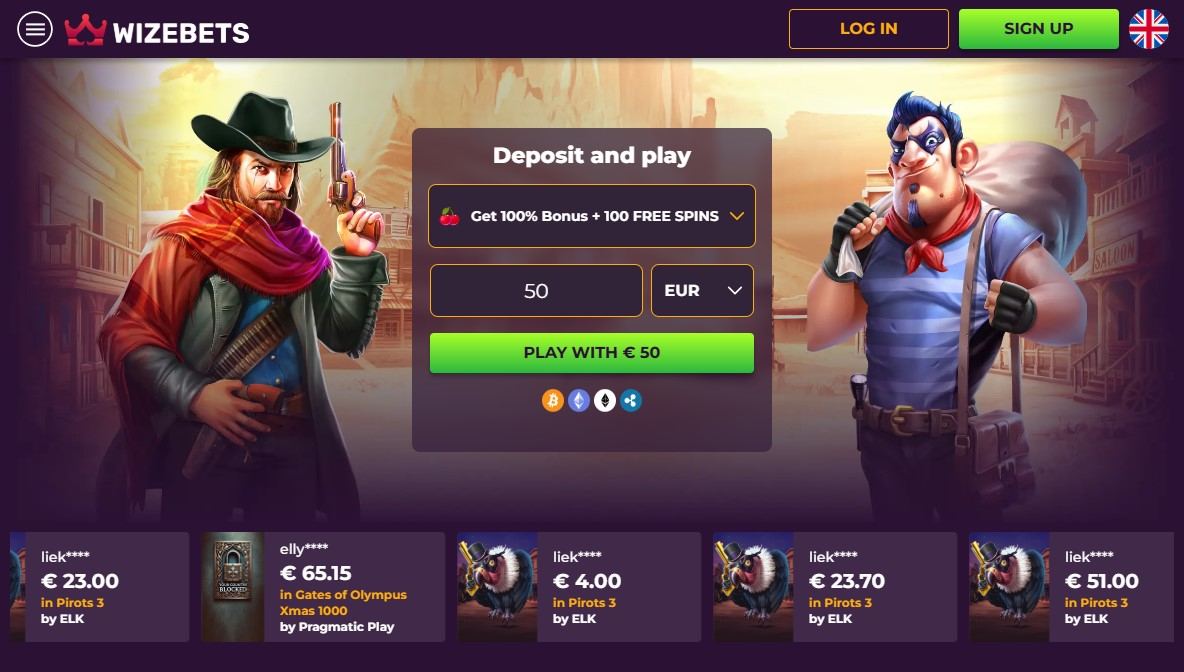

2. Wizebets – Beste mobiel casino zonder CRUKS

Wizebets is perfect voor spelers die graag onderweg gokken. De voor mobiele apparaten geoptimaliseerde site laadt snel en biedt een naadloze ervaring op alle apparaten, zonder dat je een app hoeft te downloaden.

Spellen passen zich soepel aan de schermgrootte aan en de navigatie is eenvoudig, zelfs voor nieuwe spelers. Wizebets biedt regelmatig promoties en loyaliteitsbeloningen om het spannend te houden.

De focus op gebruiksgemak en een mobiel ontwerp maakt het een goede keuze voor Nederlandse spelers die CRUKS vermijden.

- Voordelen

- Volledig mobiel geoptimaliseerd casino

- Regelmatige cashback promoties

- Gebruiksvriendelijke interface

- Nadelen

- Kleinere selectie van live dealer spellen

| Bonus | 100% tot €500 + cashbackaanbiedingen |

|---|---|

| Snelheid van uitbetaling | 24–48 uren |

| KYC | Ja |

| Betaalmethoden | VISA, Paysafecard, Skrill, Neteller, crypto |

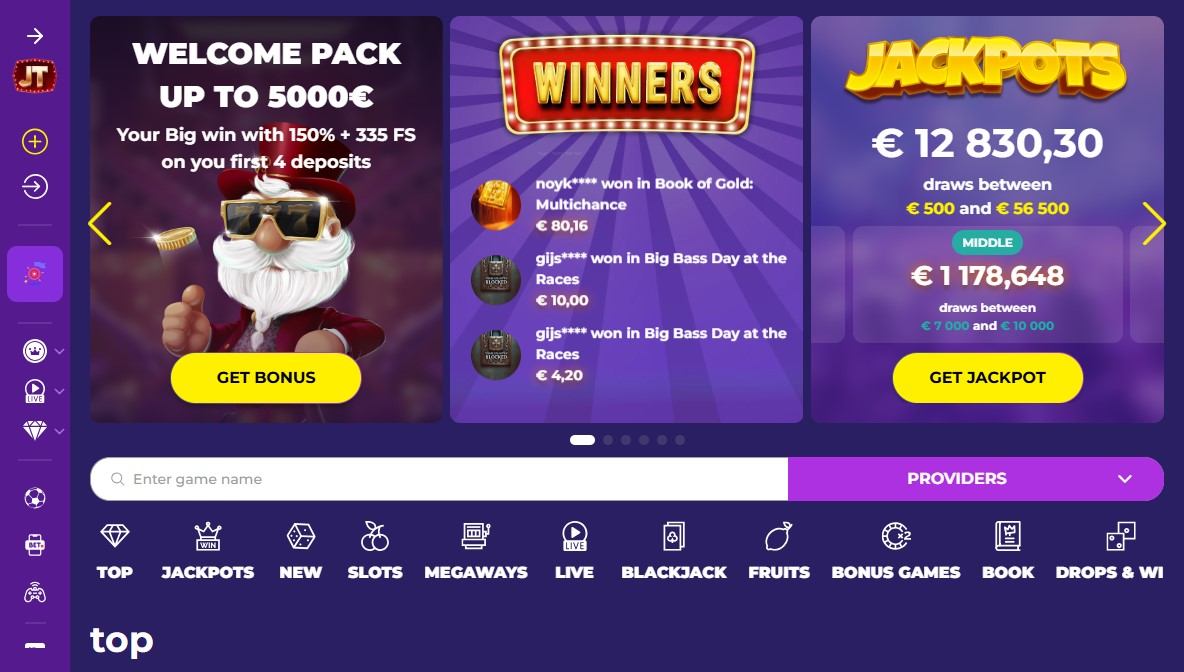

3. Jacktop – Snelste uitbetaling van alle no CRUKS casino's

Jacktop doet zijn naam eer aan met bliksemsnelle uitbetalingen en een sterke focus op jackpots. De goksite is ideaal voor spelers die groots willen winnen en snel willen uitbetalen zonder CRUKS oponthoud.

Opnames worden binnen enkele uren verwerkt, vooral voor e-wallet en crypto gebruikers. Het casino organiseert ook wekelijkse jackpot-evenementen en slotraces.Het strakke design en de snel ladende pagina's maken Jacktop een van de meest handige en efficiënte casino's op onze lijst.

- Voordelen

- Ultrasnelle uitbetalingen

- Hoogwaardige jackpot toernooien

- Schoon en responsief ontwerp

- Nadelen

- Welkomstbonus heeft hoge inzetvereisten

| Bonus | 200% tot €300 + gratis spins |

|---|---|

| Snelheid van uitbetaling | 1–24 uren |

| KYC | Ja |

| Betaalmethoden | VISA, MasterCard, Skrill, Neteller, crypto, bankoverschrijving |

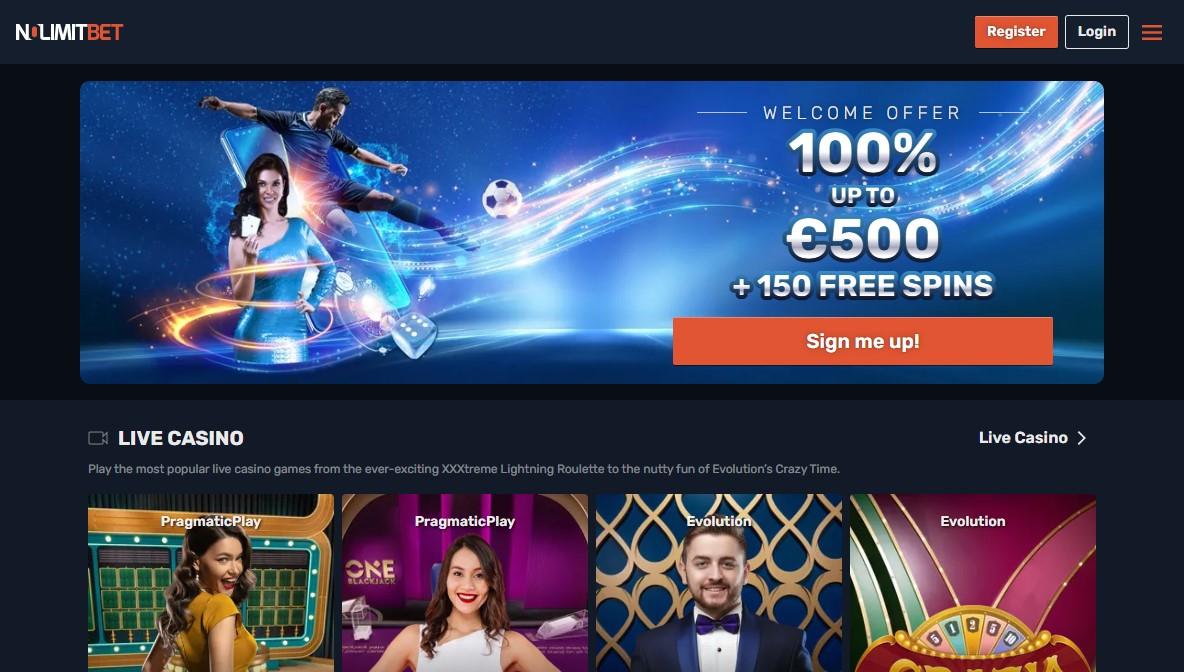

4. NoLimitBet – Top online casino Nederland voor toernooien

NoLimitBet is gemaakt voor spelers die van een uitdaging houden. Er worden regelmatig toernooien georganiseerd voor gokkasten en tafelspellen, waardoor spelers de kans krijgen om de ranglijsten te beklimmen en grote prijzen te scoren.

Zonder CRUKS-beperkingen kunnen Nederlandse spelers genieten van ononderbroken toegang tot snelle spelactie. De site is gestroomlijnd, betrouwbaar en beloont toppers.

Als je van competitie houdt en meer wilt halen uit je speeltijd, dan biedt NoLimitBet een boeiende en lonende ervaring.

- Voordelen

- Regelmatige toernooien en klassementen

- Competitieve beloningen en prijzenpotten

- Ondersteunt meerdere snelle betalingsopties

- Nadelen

- Minder variatie in casual games

| Bonus | 100% tot €500 + toernooi-entry |

|---|---|

| Snelheid van uitbetaling | 24–48 uren |

| KYC | Ja |

| Betaalmethoden | VISA, crypto, Neteller, Skrill, Paysafecard |

5. PlayBoom24 – Beste online casino voor cryptogebruikers zonder CRUKS

PlayBoom24 is het ideale online casino zonder CRUKS voor crypto-gebruikers. Het ondersteunt een breed scala aan munten en biedt onmiddellijke stortingen met bijna onmiddellijke opnames - geen bankvertragingen, geen goedkeuringen door derden.

De goksite blinkt ook uit met bonussen die zijn afgestemd op cryptostortingen en een indrukwekkende spelcatalogus, waaronder fruitautomaten met een hoge volatiliteit en aantoonbaar eerlijke titels.

Nederlandse spelers die op zoek zijn naar snelheid, privacy en moderne betaalmethoden zullen PlayBoom24 perfect vinden passen.

- Voordelen

- Volledige ondersteuning voor crypto met snelle opnames

- Royale crypto-eerste bonusaanbiedingen

- Ruime selectie van spellen met hoge volatiliteit

- Nadelen

- Geen ondersteuning voor traditionele fiatkaarten

| Bonus | 200% tot €5,000 + Cryptobonus tot 1 BTC + gratis spins |

|---|---|

| Snelheid van uitbetaling | Minder dan 24 uur |

| KYC | Ja |

| Betaalmethoden | Bitcoin, Ethereum, Litecoin, Dogecoin, Tether, bankoverschrijving |

Voordelen en Nadelen van gokken zonder CRUKS

Gokken zonder CRUKS wordt een populaire keuze voor Nederlandse spelers die op zoek zijn naar meer controle over hun spelervaring. Deze goksites verwijderen veel van de beperkingen van goklocaties met CRUKS en bieden meer vrijheid, grotere bonussen en snellere toegang. Ze komen echter ook met een paar beperkingen die het overwegen waard zijn.

| ✅ Voordelen | ❌ Nadeel |

|---|---|

| ✔ Snelle registratie zonder lange ID-controles of vertragingen | ✖ Geen bescherming door Nederlandse gokwetten of ondersteunende diensten |

| ✔ Toegang tot wereldwijde gameleveranciers met een breder aanbod aan titels | ✖ Geen CRUKS zelfuitsluiting, dus minder hulp bij probleemgokken |

| ✔ Grotere bonussen en frequentere promoties vergeleken met Nederlandse casino's | |

| ✔ Minder beperkingen op stortingslimieten, sessieduur en gameplay | |

| ✔ Cryptovriendelijke goksites met snelle, veilige opnames |

Casino’s zonder CRUKS vs. casino’s met CRUKS – Vergelijking

Vraag je je af hoe casino's met CRUKS verschillen van casino's zonder CRUKS? Hieronder vind je een overzicht van de belangrijkste verschillen – van betaalmethoden tot gameplay-functies – zodat je de spelomgeving kunt kiezen die het beste bij je behoeften en voorkeuren past.

| Kenmerk | Casino zonder CRUKS | Casino met CRUKS |

|---|---|---|

| CRUKS Bescherming | ❌ Nee | ✅ Ja |

| Spelaanbod | 🎰 Grote selectie met hoge RTP's | 🎲 Kleinere selectie, vaak lagere RTP's |

| Betaalmethoden | 💳 Meerdere opties waaronder crypto & e-wallets | 💰 Beperkt (alleen fiatvaluta) |

| Cryptostortingen | ✅ Ja | ❌ Nee |

| Rakeback | ✅ Ja | ❌ Nee |

| Geld terug | ✅ Ja | ❌ Nee |

| Bonus koopfunctie | ✅ Ja | ❌ Nee |

| Automatisch spelen | ✅ Ja | ❌ Nee |

| Casino bonussen | 🎁 Hoogwaardige, diverse aanbiedingen | 🎁 Beperkte mogelijkheden |

| Klantenservice | 🌐 Vaak beperkt of niet in het Nederlands | ✅ 24/7 Nederlandstalige ondersteuning |

| Uitbetalingen | 🚀 Snel, flexibel (inclusief crypto) | ⏳ Langzamere uitbetalingen, alleen fiat |

Spelselectie bij online casino's zonder CRUKS

Casino's zonder CRUKS bieden een bredere, meer diverse spelbibliotheek dan websites met Nederlandse regelgeving. Van duizenden gokkasten tot live dealer tafels en zelfs sportweddenschappen, deze sites komen tegemoet aan elk type speler. Hieronder vind je een overzicht van wat de top casino's zonder CRUKS momenteel aanbieden.

| Casino zonder CRUKS | Casino Spelletjes | Live Casino | Sportweddenschappen | Aantal sporten |

|---|---|---|---|---|

| 0x.bet | 4,000+ | ✅ Ja | ✅ Ja | 40+ |

| Wizebets | 4,000+ | ✅ Ja | ✅ Ja | 40+ |

| Jacktop | 3,500+ | ✅ Ja | ✅ Ja | 50+ |

| NoLimitBet | 3,200+ | ✅ Ja | ✅ Ja | 45+ |

| PlayBoom24 | 3,800+ | ✅ Ja | ❌ Nee | - |

Slots & Jackpot Games

Fans van gokkasten zullen een indrukwekkende reeks titels vinden bij casino's zonder CRUKS, waaronder spellen met een hoge RTP en progressieve jackpots. Of je nu de voorkeur geeft aan klassieke rollen of videoslots boordevol functies, deze casino sites leveren topgames van toonaangevende ontwikkelaars.

| Casino | Top Slot | Ontwikkelaar | RTP |

|---|---|---|---|

| 0x.bet | 🎰 Book of 99 | Relax Gaming | 99% |

| Wizebets | 🎰 Gates of Olympus | Pragmatic Play | 96.50% |

| Jacktop | 🎰 Blazing Bull | Kalamba Games | 97.42% |

| NoLimitBet | 🎰 Money Train 2 | Hacksaw Gaming | 96.40% |

| PlayBoom24 | 🎰 Sweet Bonanza | Pragmatic Play | 96.51% |

Klassieke tafelspellen

Klassieke tafelspellen blijven favoriet bij spelers die houden van een mix van strategie en kans. Casino's zonder CRUKS bieden een breed scala aan tafelspellen, waarvan er veel in verschillende versies zijn om aan jouw speelstijl te voldoen. Of je nu een doorgewinterde kaartspeler bent of een nieuwsgierige beginner, er valt genoeg te ontdekken.

- Blackjack – Kies uit Klassiek, Europees of Speed Blackjack, elk met zijn eigen tempo en regels.

- Roulette – Draai aan het wiel met Europees, Amerikaans of Lightning Roulette voor extra vermenigvuldigers.

- Poker – Speel varianten zoals Texas Hold'em, Caribbean Stud of Three Card Poke.

- Baccarat – Een tijdloos kaartspel dat bekend staat om zijn lage huisvoordeel en snelle rondes.

Live Casino

Live casinospellen tillen je ervaring naar een hoger niveau door echte menselijke dealers en een authentieke casinosfeer toe te voegen. Deze spellen worden in HD gestreamd, vaak met interactieve functies zoals live chat. Het komt het dichtst in de buurt van een fysiek casino, zonder dat je je huis hoeft te verlaten.

- Lightning Roulette – Voegt elektrische vermenigvuldigers toe aan het traditionele roulettespel.

- Infinite Blackjack – Eén tafel, onbeperkt aantal plaatsen en non-stop actie.

- Monopoly Live – Een unieke mix van roulette en het geliefde bordspel.

- Deal or No Deal Live – Een spelshow met hoge inzet waarin je in realtime meespeelt.

Sport Wedden Markten

Veel casino's zonder CRUKS ondersteunen ook robuuste secties voor sportweddenschappen. Van voetbal tot esports, spelers kunnen wedden op hun favoriete sporten met scherpe winkansen en flexibele wedopties. Bekijk hieronder welke websites dekking bieden op elke categorie.

| Casino | Voetbal | Tennis | Basketbal | E-sports | Paardenrennen |

|---|---|---|---|---|---|

| 0x.bet | ✅ | ✅ | ✅ | ✅ | ✅ |

| Wizebets | ✅ | ✅ | ✅ | ✅ | ❌ |

| Jacktop | ✅ | ✅ | ✅ | ✅ | ✅ |

| NoLimitBet | ✅ | ✅ | ✅ | ✅ | ✅ |

| PlayBoom24 | ✅ | ✅ | ✅ | ✅ | ❌ |

Bonussen bij casino's zonder CRUKS

Een van de grootste trekpleisters van casino's zonder CRUKS is hun royale bonusselectie. Deze casino sites gaan vaak verder dan de standaard welkomstaanbiedingen en bieden een breed scala aan doorlopende promoties die zowel nieuwe als terugkerende spelers belonen.

Hieronder staan de populairste bonussen die je kunt vinden bij no CRUKS casino's die Nederlandse spelers verwelkomen.

- Welkomstbonus – Grote stortingsmatches en gratis spins om je casino-ervaring in stijl te beginnen. Deze bonussen zijn vaak gestaffeld, zodat je beloningen kunt claimen over meerdere stortingen.

- Reload & Cashback – Extra waarde op vervolgstortingen plus cashback op je nettoverlies. Perfect om je bankroll op peil te houden en de klap te verzachten na een koude periode.

- Loyaliteit en VIP-privileges – Punten, beloningen en persoonlijke extraatjes voor frequente en high-stakes spelers. Geniet van snellere opnames, exclusieve bonussen en zelfs een speciale accountmanager.

- Crypto & No-Wager Bonussen – Speciale promo's voor crypto-gebruikers, vaak met nul of lage inzetvereisten. Deze aanbiedingen zijn ideaal voor spelers die snel toegang willen tot winsten zonder verplichtingen.

Hoe begin je met spelen op goksites zonder CRUKS?

Aan de slag gaan bij een online casino zonder CRUKS is snel en eenvoudig. Je hoeft niet door hoepels te springen-volgt gewoon een paar eenvoudige stappen en je bent binnen een paar minuten klaar om te spelen, zelfs als je jezelf eerder hebt uitgesloten in Nederland.

- Kies een betrouwbaar casino zonder CRUKS – Kies een gelicentieerde, gerenommeerde site uit onze door experts goedgekeurde lijst. Zoek naar websites met goede recensies, veilige betalingssystemen en sterke bonusaanbiedingen.

- Meld u aan en voltooi de basisverificatie – Vul uw gegevens in en verifieer uw e-mail- er zijn geen Nederlandse ID-controles of CRUKS-database opzoekingen nodig. Sommige casino's kunnen een minimale KYC vragen voor uitbetalingen, maar dit is meestal snel en probleemloos.

- Maak een storting met je voorkeursmethode – Kies uit crypto, e-wallets of kaarten voor snelle en veilige stortingen. De meeste goksites ondersteunen EUR en bieden onmiddellijke verwerking voor veelvoorkomende betalingstypes.

- Claim eventuele bonussen en begin direct met spleen – Activeer je welkomstbonus en duik meteen in je favoriete games. Van slots en live casino tot sportweddenschappen, alles is slechts een paar klikken verwijderd.

Betaalmethodes beschikbaar bij casino's zonder CRUKS

Casino's zonder CRUKS ondersteunen een breed scala aan betaalmethoden en bieden snelle en flexibele opties voor Nederlandse spelers. Of je nu de voorkeur geeft aan crypto, e-wallets of traditioneel bankieren, er is een handige methode voor elk type speler.Zonder CRUKS

Bankkaarten

Visa en MasterCard blijven twee van de populairste stortingsmethodes bij online casino's zonder CRUKS. Ze worden door bijna alle casino sites geaccepteerd, bieden onmiddellijke stortingen en zijn ideaal voor spelers die op zoek zijn naar een vertrouwde, probleemloze optie. Opnames kunnen langer duren, afhankelijk van de verwerkingssnelheid van je bank.

Overschrijvingen

Bankoverschrijvingen zijn een betrouwbare methode voor zowel stortingen als opnames. Hoewel ze niet zo snel zijn als andere opties, worden ze algemeen geaccepteerd en bieden ze een veilige manier om grotere bedragen over te maken. De meeste casino's zonder CRUKS ondersteunen SEPA overschrijvingen voor Nederlandse spelers.

E-wallets

Neteller en Skrill zijn vaak beschikbaar bij no CRUKS casino's en bieden snelle, veilige en privétransacties. Ze zijn vooral handig voor snelle geldopnames en bonusvriendelijke stortingen. De meeste spelers waarderen het gebruiksgemak en de brede compatibiliteit met casino websites.

Cryptobetalingen

Bitcoin, Ethereum en andere cryptocurrencies worden op grote schaal geaccepteerd bij casino's zonder CRUKS. Deze opties maken bliksemsnelle, anonieme transacties mogelijk zonder tussenkomst van traditionele banken. Veel goksites bieden zelfs speciale bonussen voor crypto-gebruikers.

Paysafecard

Paysafecard is een prepaid optie die perfect is voor spelers die volledige controle willen over hun uitgaven. Het stelt je in staat om te storten zonder persoonlijke bankgegevens te koppelen. Het wordt geaccepteerd bij de meeste online casino's zonder CRUKS, hoewel het niet altijd beschikbaar is voor opnames.

Veilig gokken bij een no CRUKS casino

Hoewel no CRUKS casino's meer vrijheid bieden, moet veiligheid nog steeds een topprioriteit zijn. Kies altijd voor casino sites met een geldige licentie (zoals Curaçao of MGA), bewezen eerlijk spel en veilige betaalmethoden. Kijk naar SSL-encryptie, duidelijke voorwaarden en responsieve ondersteuning. Blijf bij casino's die vermeld worden door betrouwbare bronnen, zoals deze gids, om een soepele, veilige ervaring te garanderen terwijl u buiten de Nederlandse regelgeving speelt.

Eindgedachten - Beste casino zonder CRUKS in 2026

Casino's zonder CRUKS geven Nederlandse spelers meer controle, snellere toegang en grotere bonussen. Of je nu op zoek bent naar anonimiteit, cryptobetalingen of gewoon een breuk met beperkingen, deze websites bieden een flexibel alternatief voor het rigide Nederlandse systeem. Met internationale licenties, duizenden games en royale promo's openen ze de deur naar een echt wereldwijde spelervaring. Maar onthoud: met meer vrijheid komt ook meer verantwoordelijkheid. Deze sites zijn niet verbonden met Nederlandse beveiligingen, dus het is aan jou om het slim te spelen. Kies gerenommeerde goksites, stel persoonlijke grenzen en blijf je bewust van je gewoontes.